PressureWheels

pressureWheels

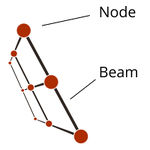

The pressureWheel is the primary method for creating wheels in BeamNG. It is a real time physical tire model made from nodes, beams, and triangles, but with many refinements, and code to automatically generate the tire geometry. The pressureWheel features tire carcass air pressure simulation based in the collision triangle system. The result is a much greater correlation to real world tire behavior compared the previous hubWheel, and a simpler, more intuitive set of parameters to tune behavior with. However, correct behavior requires correct tuning. It is recommended that the modder borrow value sets from official vehicles if the tires are a similar size and type, and then make small adjustments to taste. Keep in mind that node and beam scaling factors should be accounted for when transferring values between vehicles.

The pressureWheel replaced the hubWheel on official vehicles in version 0.3.7.4.

Wheel Definition

Example of pressureWheel definition:

"pressureWheels": [

["name","hubGroup","group","node1:","node2:","nodeS","nodeArm:","wheelDir"],

["FR", "wheel_FR", "tire_FR", "axle1", "axle2", 9999, "brakeCaliper1", -1, {"speedo":true, "nodeCoupling:":"brakeDisc1", "torqueArm:":"diff1", "torqueCoupling:":"diff2"}],

],

"name" is important for displaying in the debug, and also for integration with various functions in the game (such as the dynamic steering). Stick to using FR, FL, RR, RL for a 4 wheel vehicle.

"group" is the name of the wheel node group what the tire flexbody will assign to. The wheel generation code automatically places the inner and outer node "rings" in this group.

"hubGroup" is the name of the wheel node group what the wheel rim flexbody will assign to. The wheel generation code automatically places the axle and inner node "rings" in this group.

"node1" and "node2" are nodes that form the axle that the wheel is assembled around. The nodes themselves should be defined beforehand in a node section. These two nodes should also already have a beam between them of similar stiffness to the wheel hub beams, defined beforehand in a beam section.

"nodeS" is a stabilizing node. Each node from the hub will attach to this node with a beam. It's mostly legacy and not generally used. Putting 9999 in will disable it.

"nodeCoupling:" and "nodeArm:" form a pair of nodes to apply a braking counter torque to the suspension or body. The nodeCoupling should be defined beforehand in a node section, where the center of the brake disc would be. nodeArm should be defined beforehand in a node section, where the brake caliper would be. nodeArm and nodeCoupling should be aligned perpendicular to the wheel axle. In most cases this means they should both have the same X coordinate. If nodeCoupling is not defined, the game will default to using the inner wheel node as nodeCoupling, which may cause strange behavior in the suspension (exaggerated dive/squat when braking). Care should be taken that nodeArm and nodeCoupling are not too close together. The longer the distance between the nodes, the more stable and powerful the brakes can be. Heavier nodes will also allow more braking power and stiffness. For a typical car, they should be at least 2kg. For a large truck, as much as 5-10kg.

"torqueCoupling:" and "torqueArm:" form a pair of nodes to apply a driving counter torque to the suspension or body. The torqueCoupling should be defined beforehand in a node section, where the center of the differential output would be. torqueArm should be defined beforehand in a node section, where the source of the input torque to the differential comes from, ie, the nose/pinion of the differential, or some point on the transaxle. torqueArm and torqueCoupling should be aligned perpendicular to the wheel axle. In most cases this means they should both have the same X coordinate. If torqueCoupling or torqueArm is not defined, the game will default to not generating drivetrain torque reactions. Care should be taken that torqueArm and torqueCoupling are not too close together. The longer the distance between the nodes, the more stable the drivetrain will be. The heavier the nodes, the more stable the drivetrain will be. For example, car with a clutchtorque of 500Nm should have torque nodes that weigh at least 15kg, and at least 40cm apart, to give a rough idea. After all, a real car would need a strong and heavy differential to put down that much torque.

"wheelDir" is the direction that drive torque is applied. The correct value (1 or -1) also depends on which order you define the axle nodes.

Arguments

General Arguments

General settings determine the overall shape of the pressureWheel, and should be set to match the vehicle specifications.

Tips:

It is a good idea generally to have the tireWidth slightly narrower than hubWidth for automotive tires.

Keep numRays between 10 for small basic wheels to 20 for smoothest running. While it is true that a high numRay wheel runs smoother, this effect is mainly only noticeable at low speed (<10km/h). High numRay wheels use considerably more nodes, beams, and triangles, using up more of the CPU budget. Wheels with high numRays will also struggle to achieve the cornering and longitudinal stiffness of a real tire, leading to smooth but vague handling. They may also suffer from greater amounts of expansion at high speeds.

Node Arguments

Tips:

Don't forget about jbeam scaling factors! If present in the jbeam, they may influence the weight values you must enter.

Because part of the weight of a tire is in the sidewall and tire bead, start with a real life tire and wheel weight, but subtract some weight from the tire nodes and add it to the hub nodes.

To find the final weight of the pressureWheel, use the following formula: (nodeWeight+hubNodeWeight)*2*numRays*scaleNodeWeight. Or take a look in the node beam debug UI app in game.

Beam Arguments

Tips:

As a starting point, once you have realistic node weights, keep tire beam spring values very low, while increasing hub beam spring values until instability starts to occur. From there reduce hub beam stiffness about 5% and begin to tune tire beams.

Use the beam stress debug or node force debug visualizations (see debug menu) to make sure the tire is not unstable. Rapidly fluctuating colors or force arrows indicates instability.

Hub side beams can often handle a higher spring value than the hub tread or periphery beams. Hubs should always be as stiff as possible to limit deflection during cornering, and to limit high speed expansion of the wheel.

WheelSideBeamSpring should be very low or 0, but wheelSideBeamSpringExpansion should be very high, near instability limits. Same with the sideReinfBeam. This is to prevent high speed expansion of the wheel.

TreadBeamSpring should be very high, up to about 50-75% of the sideBeamSpringExpansion or at the limit of stability.

WheelReinfBeamSpring should be low, about 10-25% of the treadBeamSpring. Very high ReinfBeamSpring will make the tire feel more direct, but make the tire too stiff over bumps, and will reduce aligning torque/ffb feel.

WheelPeripheryBeamSpring should be nearly the same as treadBeamSpring for narrow tires, but stiffer for wide tires.

Hub damping should be kept low (2-20), but tire beams should have damping in the range of 10 to 30 for sidewall and periphery, 40-80 for tread and reinforcement.

Collision/Pressure Tri Arguments

Hints: BeamNG tires do not always benefit from higher pressures. It may make the tire feel more direct, but if it is too high, the car may become bouncy or shaky. Wide tires require less pressure than tall narrow tires. Here are some example tire pressures:

Car, typical road tire: 25-35psi

Car, racing slick: 22-27psi

Light truck: 30-50psi

Rock Crawler: 5-15psi

Heavy truck: 50-100psi

Aircraft: 100psi+

Other Arguments

| Vehicle Creation | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Get started: Introduction to Vehicle Creation | ||||||||||||||||

| ||||||||||||||||

| See also: JBeam Examples • JBeam Physics Theory |